Get Support

+91 9123517774

Revolutionizing Industries: The Power of Digital Engineering and Manufacturing Services

Introduction:

In the fast-paced and ever-evolving landscape of technology, the marriage of digital engineering and manufacturing services has emerged as a transformative force, reshaping industries and revolutionizing traditional processes. This dynamic synergy is not just a trend but a strategic imperative for companies aiming to stay competitive in today's global market. In this blog, we delve into the realm of digital engineering and manufacturing services, exploring the key components, benefits, and the profound impact they have on various sectors.

The Evolution of Digital Engineering:

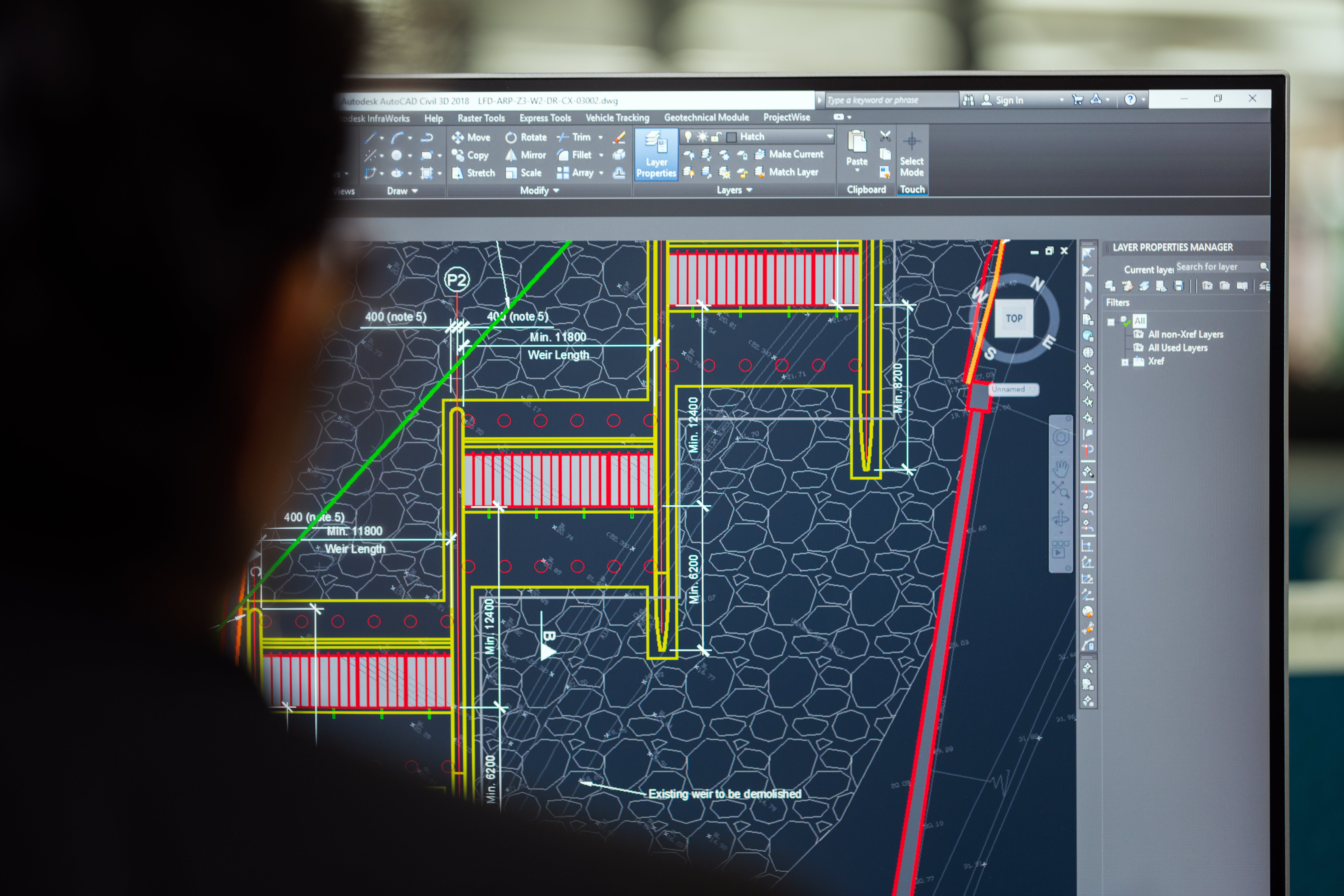

Digital engineering is more than just a buzzword; it represents a paradigm shift in how products are conceptualized, designed, and brought to market. Traditionally, engineering relied heavily on physical prototypes and manual processes, often leading to lengthy development cycles and increased costs. However, the advent of digital engineering has changed the game, allowing for virtual prototyping, simulations, and collaborative design in a digital environment.

Key Components of Digital Engineering:

- Computer-Aided Design (CAD): CAD software has revolutionized the way engineers conceptualize and design products. The ability to create detailed 3D models enables better visualization, iteration, and refinement of designs before physical prototypes are produced.

- Simulation and Analysis Tools: Digital engineering incorporates advanced simulation and analysis tools that enable engineers to predict and optimize product performance under various conditions. This not only reduces the need for physical testing but also enhances the overall quality and reliability of the final product.

- Collaborative Platforms: Cloud-based collaborative platforms facilitate real-time communication and collaboration among team members, regardless of geographical locations. This fosters a more efficient and streamlined design and development process.

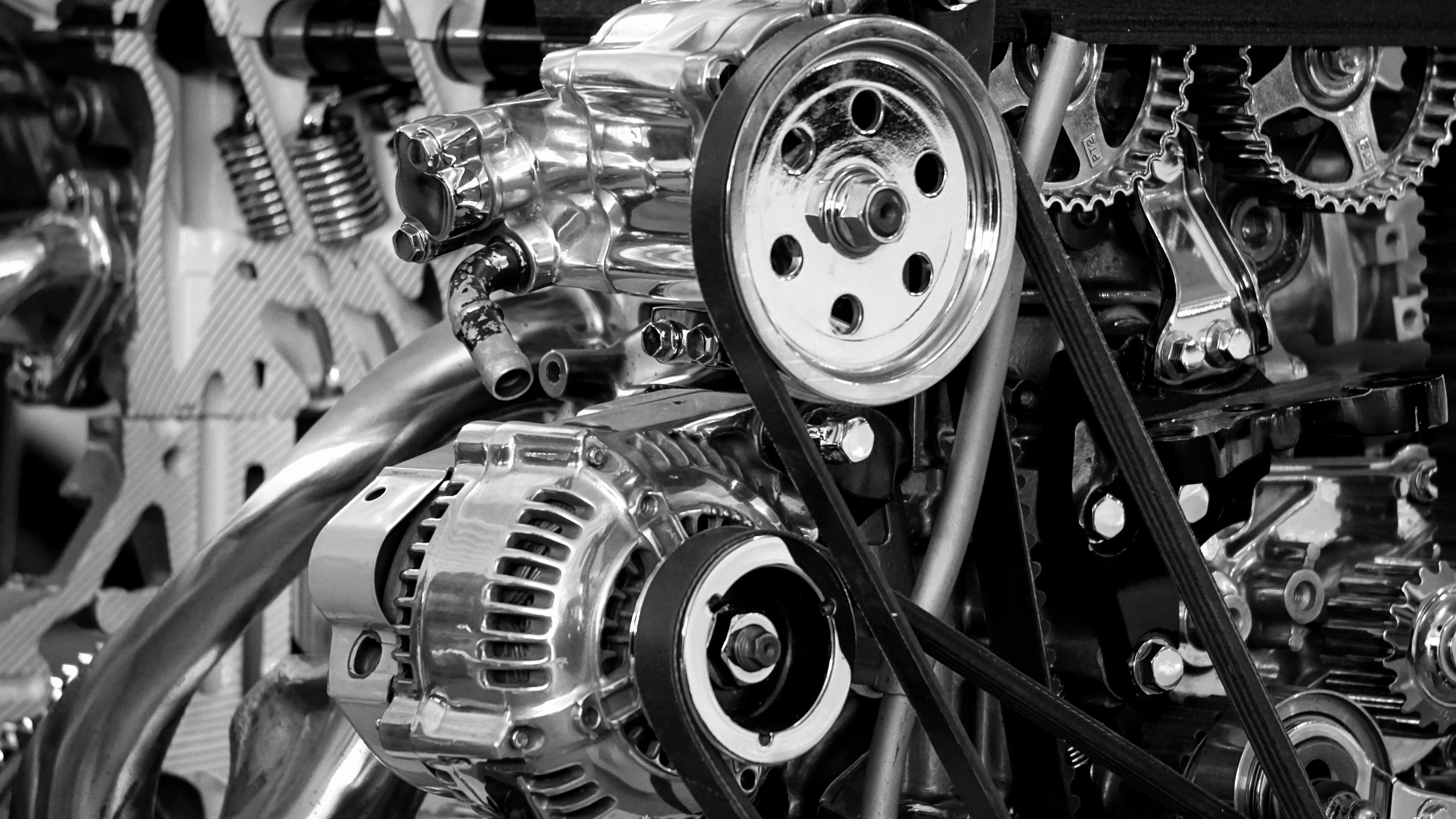

The Rise of Digital Manufacturing Services:

While digital engineering focuses on the design phase, digital manufacturing services extend the digital thread into the production realm. Digital manufacturing leverages technologies such as additive manufacturing (3D printing), CNC machining, and automation to optimize the production process, reduce waste, and enhance overall efficiency.

Benefits of Digital Engineering and Manufacturing Services:

- Accelerated Time-to-Market: By eliminating the constraints associated with physical prototypes and streamlining design iterations, digital engineering significantly reduces time-to-market, enabling companies to respond more quickly to market demands.

- Cost Savings: The virtual nature of digital engineering reduces the need for extensive physical prototyping, leading to substantial cost savings in terms of materials, labor, and time.

- Enhanced Product Quality: The ability to simulate and analyze product performance in a digital environment allows for early detection and resolution of issues, resulting in higher-quality products and fewer post-production defects.

- Customization and Personalization: Digital manufacturing services, especially additive manufacturing, open up new possibilities for product customization and personalization, catering to individual customer needs.

Impact Across Industries:

The integration of digital engineering and manufacturing services is reshaping industries across the board:

- Automotive: From designing fuel-efficient vehicles to creating safer and more ergonomic interiors, digital engineering is driving innovation in the automotive sector.

- Aerospace: In aerospace, digital engineering enables the design of lighter and more aerodynamic aircraft, contributing to fuel efficiency and reduced environmental impact.

- Healthcare: The use of digital manufacturing in healthcare has led to advancements in personalized medical devices, prosthetics, and even customized pharmaceuticals.

- Consumer Electronics: Digital engineering plays a crucial role in the rapid development of cutting-edge consumer electronics, ensuring sleek designs and high-performance products.

Conclusion:

Digital engineering and manufacturing services are not just tools; they represent a fundamental shift in how industries innovate and operate. Companies that embrace these technologies gain a competitive edge by accelerating their product development cycles, reducing costs, and delivering higher-quality products to market. As we look to the future, the continued evolution of digital engineering and manufacturing services promises even more groundbreaking advancements, unlocking new possibilities and driving innovation across diverse sectors.