Get Support

+91 9123517774

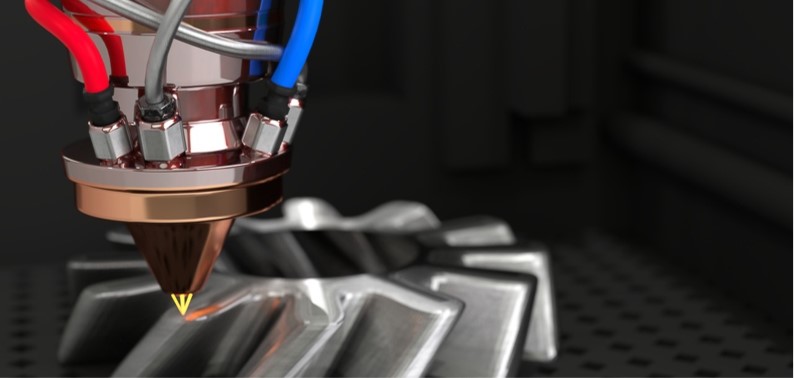

Embark on a journey of innovation with Additive Manufacturing as it reshapes the landscape of the steel industry. This groundbreaking technology is propelling the industry into a new era, where traditional production methods are giving way to a more efficient and flexible manufacturing process.

The Rise of Additive Manufacturing in Steel

Additive Manufacturing, often referred to as 3D printing, is revolutionizing how steel components are produced. Unlike traditional subtractive manufacturing processes, additive manufacturing builds objects layer by layer, offering unprecedented design freedom and resource efficiency. In the steel industry, this translates to enhanced product customization and reduced material waste.

.jpg)

Key Advantages of Additive Manufacturing

The adoption of additive manufacturing in the steel sector brings several advantages:

- Complex Geometries: 3D printing allows for the creation of intricate and complex steel structures that would be challenging or impossible to achieve with conventional methods.

- Reduced Lead Times: Additive manufacturing accelerates the production process, leading to shorter lead times for delivering steel components.

- Customization: Manufacturers can tailor steel products to meet specific requirements, catering to diverse industry needs.

- Material Efficiency: Traditional methods often result in significant material waste. Additive manufacturing optimizes material usage, minimizing waste and lowering costs.

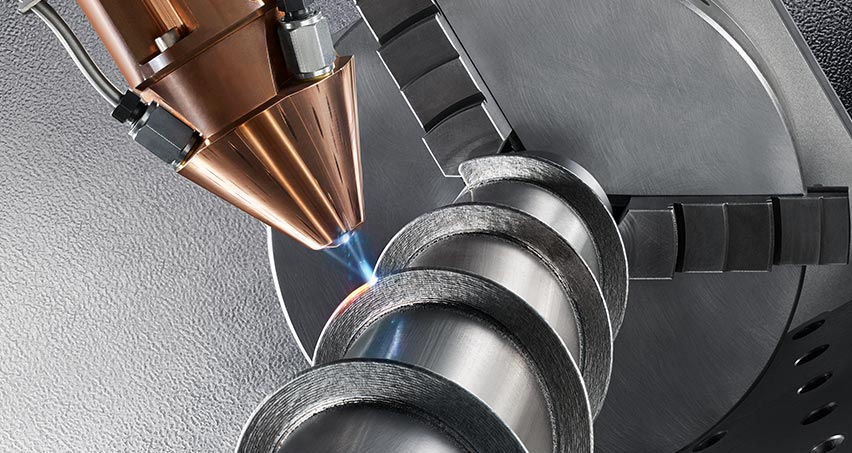

Applications in the Steel Industry

The applications of additive manufacturing in the steel industry are vast and continually expanding:

- Prototyping: Rapid prototyping allows for quick iterations and testing of steel components before full-scale production.

- Tooling and Molds: Creating intricate tooling and molds with 3D printing enhances manufacturing capabilities.

- Custom Parts: Industries can now order bespoke steel parts tailored to their specific requirements, fostering innovation and efficiency.

Challenges and Future Prospects

While additive manufacturing holds immense promise, challenges such as material limitations, production speed, and post-processing requirements need to be addressed. Ongoing research and development are focused on overcoming these hurdles, paving the way for a future where additive manufacturing becomes more mainstream in the steel industry.

Conclusion: Shaping the Future of Steel Production

The integration of additive manufacturing marks a transformative period for the steel industry, unlocking new possibilities and redefining established norms. As this technology continues to evolve, the steel sector is poised for greater efficiency, sustainability, and innovation, heralding a future where the traditional boundaries of production are transcended.